The benefits of reducing the investment in inventory are substantial, which can lead a company to pare away too much inventory. Another option is to retain a backup supplier for key inventory items. This risk can be mitigated through the use of expensive overnight delivery services when shortages occur. Low JIT inventory levels make it more likely that any problem in the supplier pipeline will lead to a shortage that will stop production. There is one key problem with JIT inventory, but it is a large one. And a final advantage is that it is much easier to implement engineering change orders to existing products, because there are few existing stocks of raw materials to draw down before you can implement changes to a product. Furthermore, a thoroughly implemented JIT system should shorten the amount of time required to manufacture products, which may decrease the quoted lead times given to customers placing orders. A further advantage is that defective inventory items are more easy to identify and correct, resulting in lower scrap costs. Another advantage is that, with inventory levels so low, there is little risk of having much obsolete inventory. One advantage of JIT inventory is that the investment in working capital is minimized. There are a multitude of improvements related to JIT inventory, particularly in relation to reduced cash requirements and the ease with which manufacturing problems can be uncovered. When suppliers are located quite close to a company's production facility, the shortened distances make it much more likely that deliveries will be made on time, which reduces the need for safety stock.

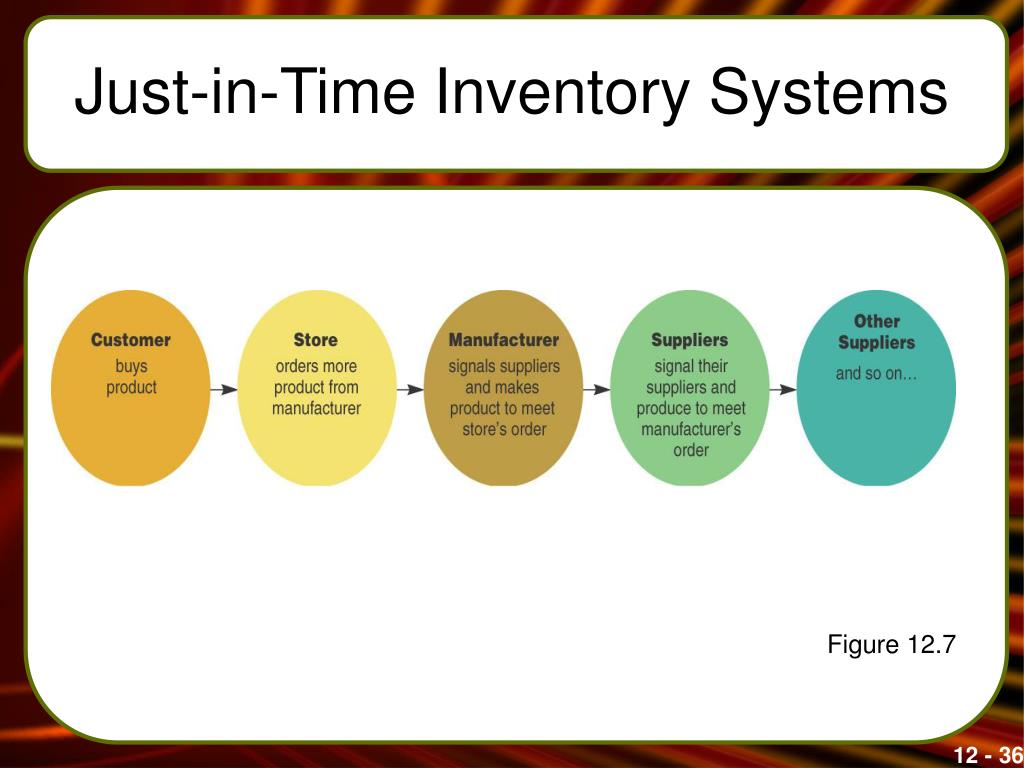

Supplier quality is certified in advance, so their deliveries can be sent straight to the production area, rather than piling up in the receiving area to await inspection. Deliveries are made with the smallest possible quantities, possibly more than once a day, which nearly eliminates raw material inventories.Ĭertification. Production cells are arranged close together, so there is less work-in-process inventory being moved between cells.ĭelivery quantities. Doing so also eliminates the work-in-process queues that typically build up in front of a more specialized work station.Ĭompressed operations. Employees walk individual parts through the processing steps in a work cell, thereby reducing scrap levels. Fast equipment setup times make it economical to create very short production runs, which reduces the investment in finished goods inventory. Under the JIT concept, inventory may be reduced by the following means: This type of system is called a " pull" system. Doing so eliminates a considerable investment in inventory, thereby reducing the working capital needs of a business. The intent of a JIT system is to ensure that the components and sub-assemblies used to create finished goods are delivered to the production area exactly on time. Just-in-time inventory is the reduced amount of inventory owned by a business after it installs a just-in-time manufacturing system.

0 kommentar(er)

0 kommentar(er)